Building a Virginal: Preparing the Jacks

May 10, 2023

Roscoe, N.Y.

One week ago today — on Construction Day 20 — I prepared all 55 jacks for the Zuckermann Troubadour Virginal that I’m building. As I discussed in my previous blog entry, the jacks connect the keyboard with the strings (i.e., wires). They come supplied with tongues held by a stiff little metal wire that allows them to swivel, and a slot for some damping cloth:

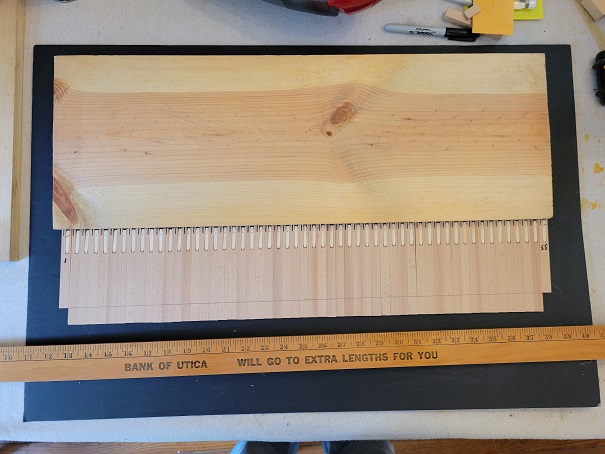

The first job is to cut them down to size. The construction manual recommends to stick a plectrum in two of them, drop them into the lowest and highest slots on the box guide, and estimate how much to cut so that the plectra sit right underneath the strings. Here’s the result:

The jacks are labeled 1 for the lowest bass jack 55 for the highest treble jack. The difference results from the thickness of the wires and the geometry of the keyboard. I hesitated to make them as short as they should have been for fear of making them too short. (It’s possible to fix jacks that are too short by gluing wood to the bottom or even using some tape, but it’s a hassle.) Later they will be shortened even more.

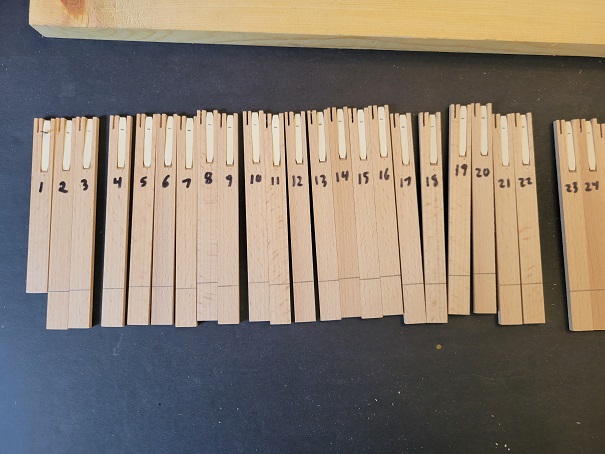

I then lined up the remining jacks and marked them for cutting proportionally to the lengths of the first and last jacks:

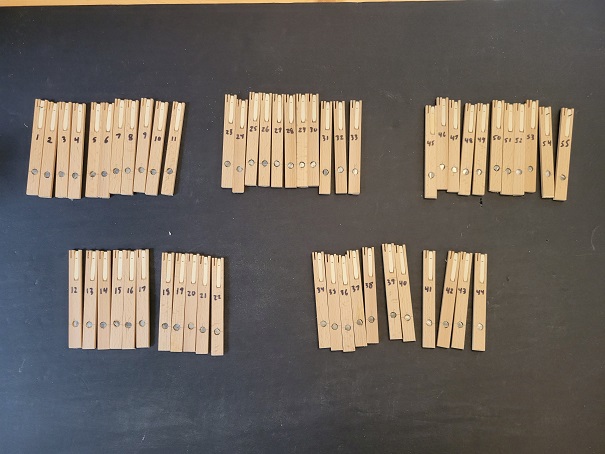

Before cutting, they are numbered and forever destined to be associated with specific keys and wires of the virginal:

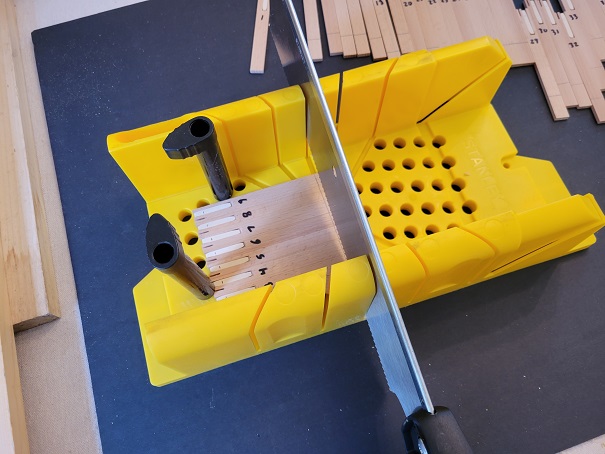

I was a little nervous about cutting something as small as a jack on a power chop saw, so I used a miter box, lining up consecutive jacks and securing them before sawing. After putting a nice groove in them like this, I then resorted to finishing them individually.

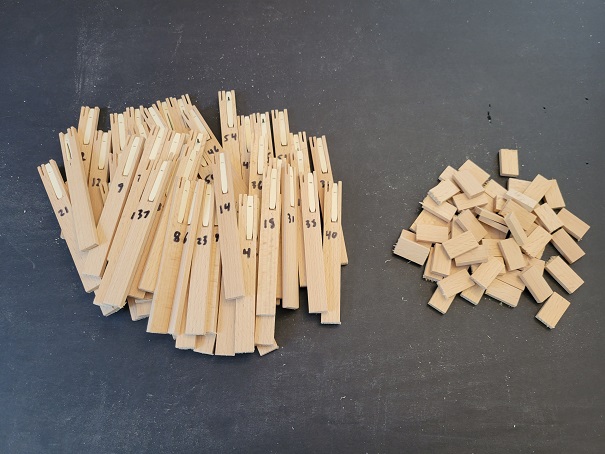

All done, and I’m left with 55 shortened jacks and 55 pieces of scrap:

The jacks must be given a little more heft with chunks of lead. On page 49 of The Troubadour Virginal Construction and Maintenance Manual, Ed Kittrick explains:

Virginal jacks are generally short, which makes them very light — sometimes too light. The old builders dealt with this in one of two ways: either they made the jacks thicker, thus providing more mass, or they drilled a hole in the jack and inserted some lead. Our jacks weigh just about 3 grams when cut to size,

Actually, more like 3¼ grams based on a little electronic scale I have.

and that’s too light; they won’t return with the smartness we’d like. So drill a 17/64” hole in each jack, centered about 1” from the bottom.

This I did:

Kottick continues:

With your hobby saw, slice 1/8” (the thickness of the jacks) pieces of lead off the rod supplied.... The lead brings the weight of the jack up to 5 grams, which makes it work like a charm!

Well, not exactly. It’s fairly easy to determine that a ⅛” length of ¼” diameter lead wire is not much more than 1 gram. (For example, Wikipedia says that lead has a density of 11.34 grams per cubic centimeter, or 185.8 grams per cubic inch. An inch of ¼” diameter lead wire is π(⅛)² or 0.0491 cubic inches, so an inch of ¼” diameter lead wire is 9.12 grams, and ⅛ of that is 1.14 grams)

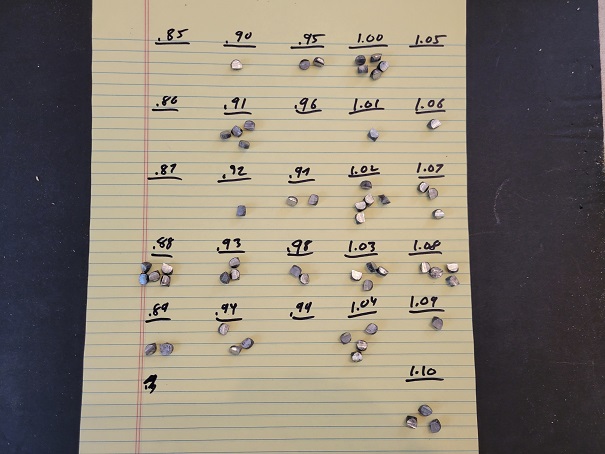

After cutting the ⅛” lengths, Kottick suggests dividing them into three piles based on length, and use the shorter (lighter) ones for the treble jacks and the longer (heavier) ones for the bass jacks. I cut my lead with a pair of heavy snippers, and I couldn’t tell which were short and which were long, so I adopted a more precise method. I weighed each one on a little electronic scale. I rejected anything not within the range 0.85 grams to 1.10 grams, and then sorted them:

I pounded the jack weights into the jacks with a hammer and a ¼” punch, which I would have used for the keyboard weights if I had known then that such a thing existed:

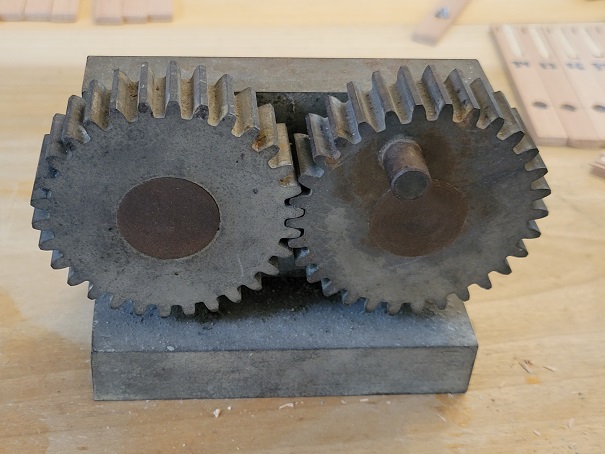

After a few, I wished I had some kind of metal anvil to use as a base, and I remembered I had a heavy assemblage of gears that I believe my father made in metal shop in high school:

It doesn’t really do anything, but if you turn the gear on the right — which takes some effort — the one on the left will also turn. But the back made a perfect surface for supporting the jacks while banging in the lead:

In the process of banging the jack weights into the jacks, I only split two of them. Fortunately I had some wood glue and vises nearby from an earlier stage of the project.

At the conclusion of Construction Day 20, all the jacks were now ready for plectra.